Have you ever wondered how things like in line skate wheels and electric motors spin so smoothly and quietly? The answer can be found in a neat little machine called a bearing. It makes many of the machines we use every day possible. Without it, we would be constantly replacing parts that wore out from friction. How Bearing Works:Things roll better than they slide. The wheels on your car are like big bearings. If you had something like skis instead of wheels, your car would be a lot more difficult to push down the road.That is because when things slide, the friction between them causes a force that tends to slow them down. But if the two surfaces can roll over each other, the friction is greatly reduced. It reduces friction by providing smooth metal balls or rollers, and a smooth inner and outer metal surface for the balls to roll against. These balls or rollers "bear" the load, allowing the device to spin smoothly. Types:

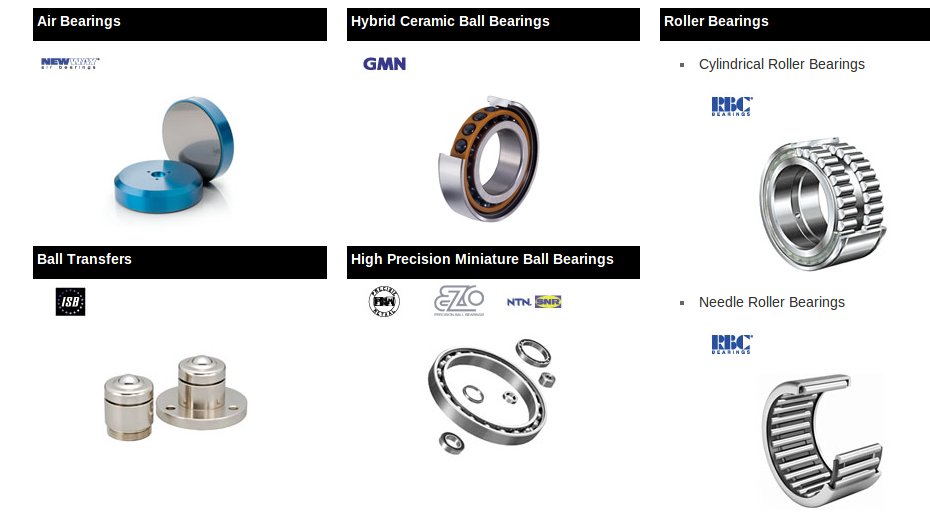

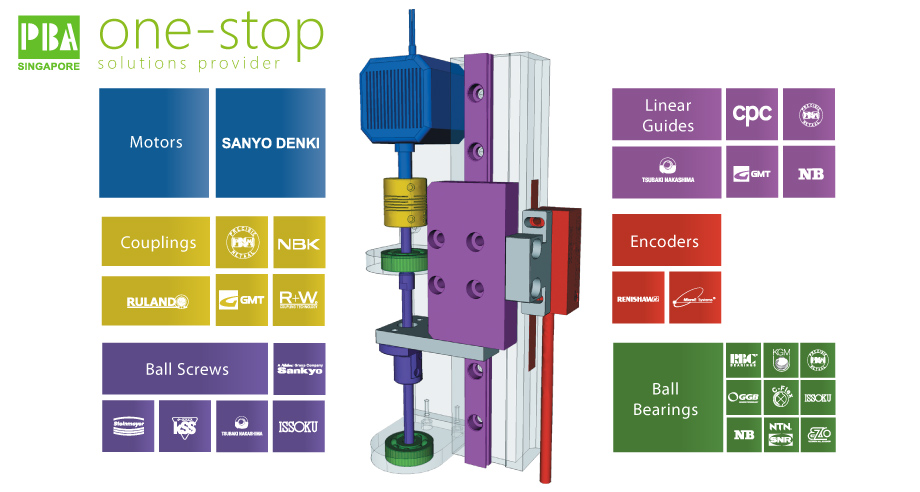

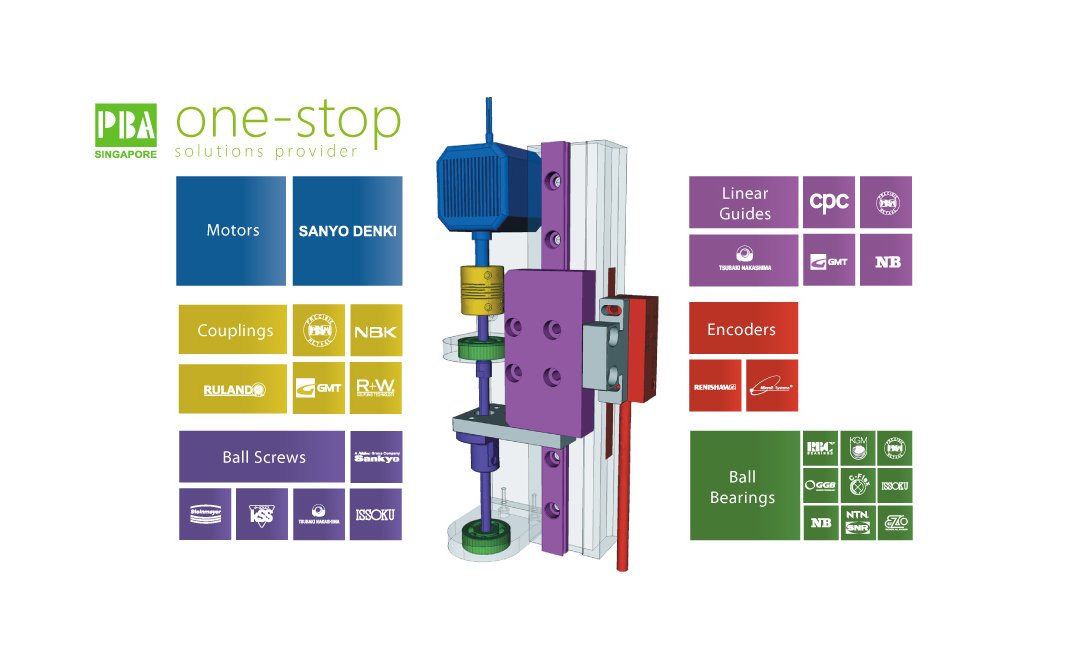

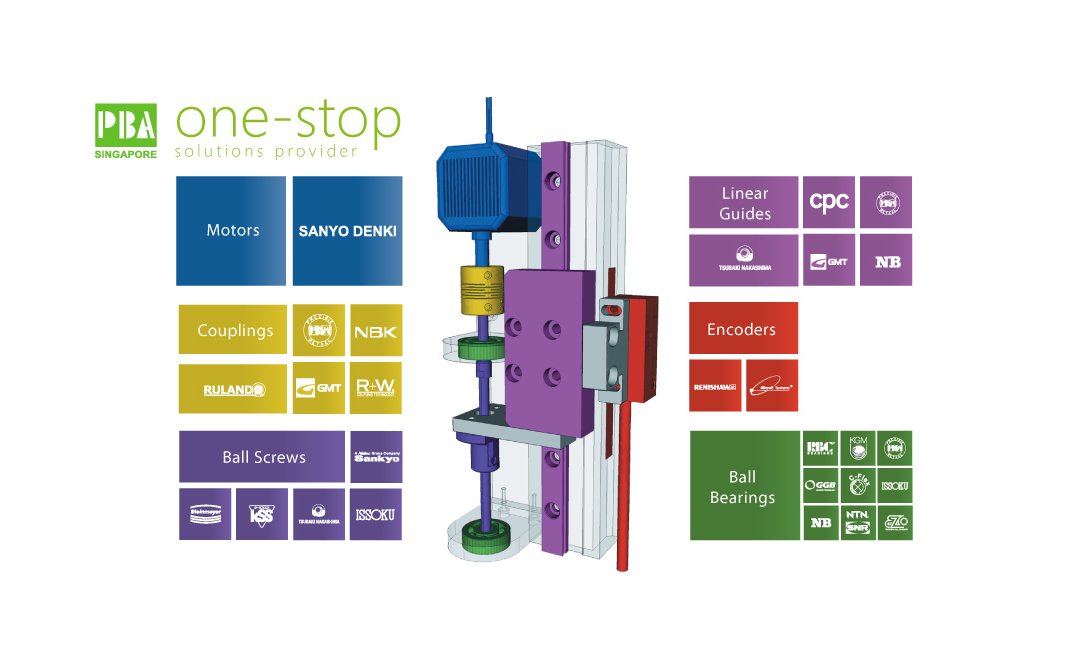

There are many types of bearings, each used for different purposes. These include Hybrid Ceramic Ball Bearings, Air Bearings, Roller Bearings, Ball Transfers, High Precision Miniature Ball Bearings, High Temperature Bearings, Oscillating Bearings, Deep Groove Ball Bearings, Filament Wound Bearings, Plastic Bearings, Thin Section Bearings and Insert Ball Bearings with Housing. Leading Singapore Bearing Distributor:PBA (S) Pte Ltd is an integrated, one-stop solutions provider of bearing solutions, linear systems and other mechanical precision components as well as OEM equivalent parts. For over 20 years, PBA (S) has continued to provide the highest quality products and coupled with superior value-added customer service. PBA (S) Pte Ltd

505 Yishun Industrial Park A

PBA Building

Singapore 768733

Tel : +(65) 6576 6766

General Enquiry / Sales: [email protected]

Website : www.pba.com.sg

A bearing is a tool used to reduce the friction that occurs in machines. Friction is a kind of force which opposes the movement of a surface in sliding or rolling motion over another surface with which it is in contact. Bearings bear the frictional force which is set up by the moving surface of a machine part.

Bearings are categorized according to how they operate and the motions that they allow. The two common motions are linear and rotary. Bearings which allow linear motions are called linear bearings. These bearings allow motion in a straight line. An example of linear motion is the pulling and pushing of a drawer. Rotary motions, on the other hand, involve one direction rotation and oscillation, wherein the motion goes only through a part of a cycle, such as in the case of a wheel. Rotary bearings, therefore, allow motions which are concentrated on a center, like a wheel on a shaft.

For more Bearings and Components , please visit

http://www.pba.com.sg/

For enquiries on any of our products, email us at enquiries[@]pba.com.sg or call us at +(65) 6576 6766

There are different types of ball bearings available to cater to the needs of various industries. Ball bearings are the most common of them all. The other options include Cylindrical Roller Bearings, Needle Roller Bearings, Spherical Roller Bearings and more.

Ball bearings have a wide usage and are found in number of objects and accessories. The usage varies from industries like industrial, manufacturing, automobile, electrical, mechanical, computing and many more.

The specifications and features of bearings can vary as per their types they can be custom made to suit the needs and can also be made available as per industry requirements. Ball bearings have the capability to handle both radial and thrust loads, and are usually found in applications where the load is relatively small. They are capable of performing at high speed. But the bearing should not be overloaded as it may cause the balls to get ruined.

Bearing suppliers have a greater requirement in automobile sector and make its presence felt many ways. The quality and performance matters to a huge extent and has substantial effect on pricing and availability. The exact needs are determined to serve the customers in the right way to come up with desired solutions.

For more Bearings and Components , please visit

http://www.pba.com.sg/products/types-and-brands/bearings-and-components.html

For enquiries on any of our products, email us at enquiries[@]pba.com.sg or call us at +(65) 6576 6766

The balls and rings themselves have to be made from high performance materials; regular iron will not meet the required FDA and USDA standards. A common choice within industry is to use stainless steel balls and rings. They combine high tensile strength with good corrosion resistance and will not contaminate food. However, they are one of the most expensive options, so other materials have been designed as balls as well.

Plastic blends and can be utilized by themselves or with stainless steel, especially in plain or non-rolled style industrial bearings. Coated iron is a less expensive option as well. A chrome coating will improve the balls' hardness and corrosion resistance and increase their durability. Zinc coatings are also common for improving corrosion resistance and preventing contamination.

For more information on all kinds of bearings, please visit the site www.PBA.com.sg

email us at enquiries[@]pba.com.sg or call us at +65 6576 6766

Bearings are important to the machines we use everyday, for without them, we would need to frequently replace broken machine parts due to the wear and tear of friction.

A bearing is a tool used to reduce the friction that occurs in machines. Bearings are categorized according to how they operate and the motions that they allow. The two common motions are linear and rotary. Bearings which allow linear motions are called linear bearings. These bearings allow motion in a straight line. An example of linear motion is the pulling and pushing of a drawer. Rotary motions, on the other hand, involve one direction rotation and oscillation, wherein the motion goes only through a part of a cycle, such as in the case of a wheel. Rotary bearings, therefore, allow motions which are concentrated on a center, like a wheel on a shaft.

PBA (S) is an integrated, one-stop solutions provider of bearing solutions, linear systems and other mechanical precision components as well as OEM equivalent parts.

For enquiries on any of our products, email us at enquiries[@]pba.com.sg or call us at +65 6576 6766

For more information, please visit PBA.com.sg

Have you ever wondered how cars and other motor vehicles run smoothly and quietly? All these machines run smoothly with the help of smaller machines called bearings.A bearing is a tool used to reduce the friction that occurs in machines.

Bearings are categorized according to how they operate and the motions that they allow. The two common motions are linear and rotary. Bearings which allow linear motions are called linear bearings. These bearings allow motion in a straight line. An example of linear motion is the pulling and pushing of a drawer. Rotary motions, on the other hand, involve one direction rotation and oscillation, wherein the motion goes only through a part of a cycle, such as in the case of a wheel. Rotary bearings, therefore, allow motions which are concentrated on a center, like a wheel on a shaft.

For enquiries on any of our products, email us at enquiries[@]pba.com.sg or call us at +65 6576 6766

For more information, please visit PBA.com.sg

Established in 1987, PBA (S) Pte Ltd distributes mechanical components including high-performance bearing solutions and applications as well as compatible OEM equivalent parts. PBA (S) Pte Ltd was awarded the prestigious Enterprise 50 Award on the first year we joined in 2007, and for a second time in 2011. In the same year, PBA (S) Pte Ltd was also selected as one of the top 5 finalist under the Innovation (SME) Category in the ASEAN Business Awards (ABA) 2011. PBA (S) was also recently awarded the Promising SME 500 2013. For enquiries on any of our products, email us at [email protected] or call us at +65 6576 6766 For more information, please visit PBA.com.sg

|

RSS Feed

RSS Feed